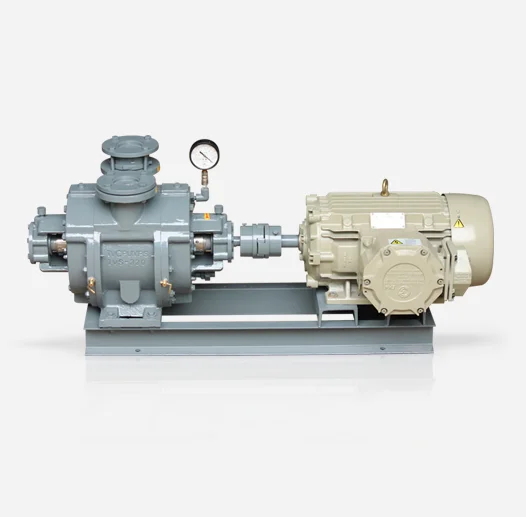

Liquid ring vacuum pumps are bendy and inexperienced gadgets widely used all through industries for various packages. But how exactly do they art work? This article explores their precise mechanism, functionality, and blessings with the aid of answering key questions about their operation.

What Are Liquid Ring Vacuum Pumps?

These pumps are regarded for their capacity to cope with wet gases, vapors, or maybe small quantities of liquid inside the suction flow into. They’re ideal for industries requiring dependable and constant vacuum systems, which incorporates chemical processing, food packaging, and environmental engineering.

How Does the Mechanism of Liquid Ring Vacuum Pumps Work?

The working precept of liquid ring vacuum pumps is especially honest but noticeably effective. The pump includes an impeller hooked up eccentrically inside a cylindrical casing. During operation, the casing is in component filled with a liquid (regularly water or every other like minded liquid). As the impeller rotates, centrifugal pressure pushes the liquid outward, forming a liquid ring around the casing.

The impeller blades create wallet of diverse volume among themselves and the liquid ring. As the wallet expand, air or fuel is drawn into the pump, and as the pockets settlement, the gas is compressed and expelled through the release port. This non-stop cycle creates and maintains a vacuum in the device.

Why Are Liquid Ring Vacuum Pumps Preferred for Wet Applications?

One of the standout capabilities of liquid ring vacuum pumps is their potential to cope with wet gases, saturated vapors, and drinks with out harm or loss of overall performance. The liquid sealant no longer best creates the vacuum however additionally cools the pump at some point of operation, stopping overheating.

This makes them an super choice for applications like vacuum distillation, deaeration, and handling of condensable vapors. Their format guarantees minimum wear and tear, even in tough environments, which provides to their toughness.

What Are the Advantages of Liquid Ring Vacuum Pumps?

These pumps provide numerous advantages, making them a well-known preference in the course of industries:

Durability: Liquid ring pumps are sturdy and constructed to resist traumatic situations.

Low Maintenance: With fewer transferring additives, they require tons much less protection compared to specific pump sorts.

Versatility: They are able to managing a large range of gases and beverages.

Eco-Friendly: The liquid used can regularly be recycled within the device, reducing waste.

Quiet Operation: These pumps function with minimal noise and vibration, making sure a higher taking walks environment.

Which Industries Use Liquid Ring Vacuum Pumps?

The adaptability of liquid ring vacuum pumps makes them appropriate for a variety of sectors, consisting of aspect:

Chemical and pharmaceutical applications include vacuum drying, distillation, and filtering methods.

Food and liquids: For packing, sealing, and upkeep.

Oil and gasoline: For vapor healing and processing.

Environmental engineering is worried with wastewater treatment and the control of air pollution.

How are Liquid Ring Vacuum Pumps Maintained?

Proper preservation guarantees that the ones pumps carry out optimally for years. Here are a few key maintenance practices:

Regularly test the liquid sealant diploma and first-class.

Inspect the pump for signs and symptoms and symptoms of wear and tear and tear or damage to the impeller or casing.

Clean and get rid of debris from the pump to save you blockages.

Monitor the temperature and stress to ensure they continue to be internal secure working limits.

These steps help prevent downtime and highly-priced maintenance on the identical time as preserving efficiency.

How Do Liquid Ring Vacuum Pumps Compare to Other Vacuum Technologies?

When evaluating liquid ring vacuum pumps to other vacuum era, their key differentiators are their functionality to deal with moist situations and their simplicity of operation. Unlike dry vacuum pumps, which may battle with moisture, liquid ring pumps thrive in such conditions.

However, they may now not be as electricity-green as a few superior dry vacuum systems. For industries requiring a reliable, low-maintenance answer for moist applications, liquid ring vacuum pumps are often the pinnacle preference.

What Are the Common Applications of Liquid Ring Vacuum Pumps?

These pumps are applied in some of tactics, in conjunction with:

Vacuum Condensation: Removing air and gases from systems to hold pressure.

Vapor Recovery: Collecting and condensing vapors for reuse or disposal.

Vacuum Packaging: Preserving food and one of a kind perishables with the aid of using doing away with air.

Gas Compression: Compressing gases for storage or shipping.

Their functionality to deal with each gases and liquids makes them worthwhile in those techniques.

How Are Liquid Ring Vacuum Pumps Evolving with Modern Technology?

With upgrades in materials and engineering, liquid ring vacuum pumps have become more efficient and sustainable. Improved sealants, corrosion-resistant substances, and smart tracking structures are enhancing their overall performance and reliability.

Additionally, producers are focusing on green designs that lessen water utilization and power consumption, aligning with international sustainability dreams.

What About Elmo Rietschle Vacuum Pumps?

While liquid ring vacuum pumps are terrific for moist packages, Elmo Rietschle vacuum pumps are also broadly diagnosed for his or her versatility and performance. These pumps are designed to satisfy severa business dreams, presenting progressive answers for vacuum and pressure structures.

Their superior technology and customizable options reason them to a strong competitor inside the vacuum pump market. Understanding your precise necessities will assist determine whether or not or no longer liquid ring or Elmo Rietschle vacuum pumps are the higher fit in your desires.

Conclusion

Liquid ring vacuum pumps stand out as a dependable and flexible answer for numerous industrial applications. Their potential to cope with wet conditions, coupled with their durability and coffee maintenance, makes them a favored preference for lots industries.

Whether you’re thinking about liquid ring or Elmo Rietschle vacuum pumps, know-how their mechanisms and blessings is fundamental to growing the proper desire to your operations. With the proper vacuum pump, you may decorate performance, lessen charges, and acquire superior overall performance.

0 Comments